Hydro turbine

-

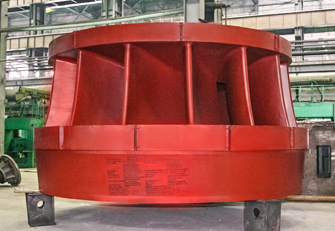

Kaplan type turbines

- with oil-filled runners and ecologically clean runners(without oil in caveof bushing of runner, in area of blades sealing) for heads 6-70 m with capacity 10-230 MW

-

Francis type turbines

- for head 30-405 m with capacity 10-645 МW

-

Horizontal bulb turbinesе

- with capacity 5-40 МW

-

Reversible hydraulic machines

- for head 50-230 m with capacity 40-400 МW

-

Propeller type hydro turbines

- for head 10-40 m with capacity 120 MW

-

Butterfly valves dia

- from 1,0-7,6 m for head 10-230 m

-

Spherical valves dia

- from 0,8-4,2 m for head up to 950 m

-

Embedded cylindrical valves dia

- from 3,43-10,74 m for head up to 310 m

-

Hydro turbines for small HPP

- up to 25 МW

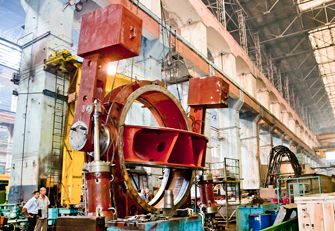

Since 1953, enterprise manufactures all kinds of reaction-type hydro turbines and inlet valves for domestic and foreign HPP and HPSPP.

Development and design of hydro power equipment carries out by special design office “Turbohydromash”.

SDO “Turbohydromash”, due to availability of skilled specialists and own experimental facilities, performs entire necessary work package of research and design, design and engineering developments for creation of modern hydraulic machines, including:

- Flow parts for all kinds of reaction hydro turbines, reversible hydraulic machines and inlet valves designing;

- New hydro turbine equipment design, entire necessary scope of hydrodynamic, strengthening and other special calculations realization;

- Projects of modernization of equipment worked its service life performance;

- Power –cavitational, pulsating, erosion, power tests of hydro turbine models, reversible hydromachines and also research of assemblies and machinery;

- Condition survey of equipment, are subject to rehabilitation, using modern technical facilities, including testing at HPP;

- Residual life prediction of parts of equipment, subject to reconstruction, using physic-mathematical model of destruction;

- Acceptance testing of hydro turbines` and reversible hydraulic machines` models, including modernized water passages at special benches o the laboratory;

- Supervise of equipment erection;

- Commissioning and start-adjusting testing;

- Warranty full scale testing of hydro turbine equipment;

- Warranty and service maintenance of equipment.