Metallurgical Production

Foundry has following capabilities:

Casting of workpieces of carbon, alloyed and stainless steels with weight 100 up to 10 000 kg.

- Smelting of steel implements on Electric Arc Furnaces with use of microalloying

- Implements blowing of metal with oxygen in furnace and argon in dipper

Workpices of valuable metals with weight 1 up to 450 kg:

- Bronze (grade Бр010Ф1, Бр05Ц5С5, БрА9Ж3)

- Aluminium АЛ-2

- Brass ЛЦ40Мц3Ж

Model workshop manufactures:

- Wooden models for foundry of any complexity

Receiving of high-quality workpieces ensured by using of modern molding equipment and mixes on basis of furane rosins.

Forge has following capabilities:

Manufacturing of forged pieces by methods:

- Open forging

- Forging with skid tool with hummers weight of drop parts 150 up to 3150 kg.

Grades of steel:

- Carbon structural, low-alloy, alloy, high-alloy, corrosion-resistant, heat-resistant.

Range:

- Disks and rolling rings – diameter up to 900 mm, weight up to 300 kg.

- Shafts – diameter of barrel up to 300 mm, length up to 2000 mm, weight up to 400 kg.

- Bars, plates and other forged piece – weight up to 400 kg.

- Shaped forgings

Workpieces are:

- Rolled metal of circular and square section with size up to 300 mm

- Forged ingots with weight 675 kg

Cutting of workpieces implements on cutting band machine tools.

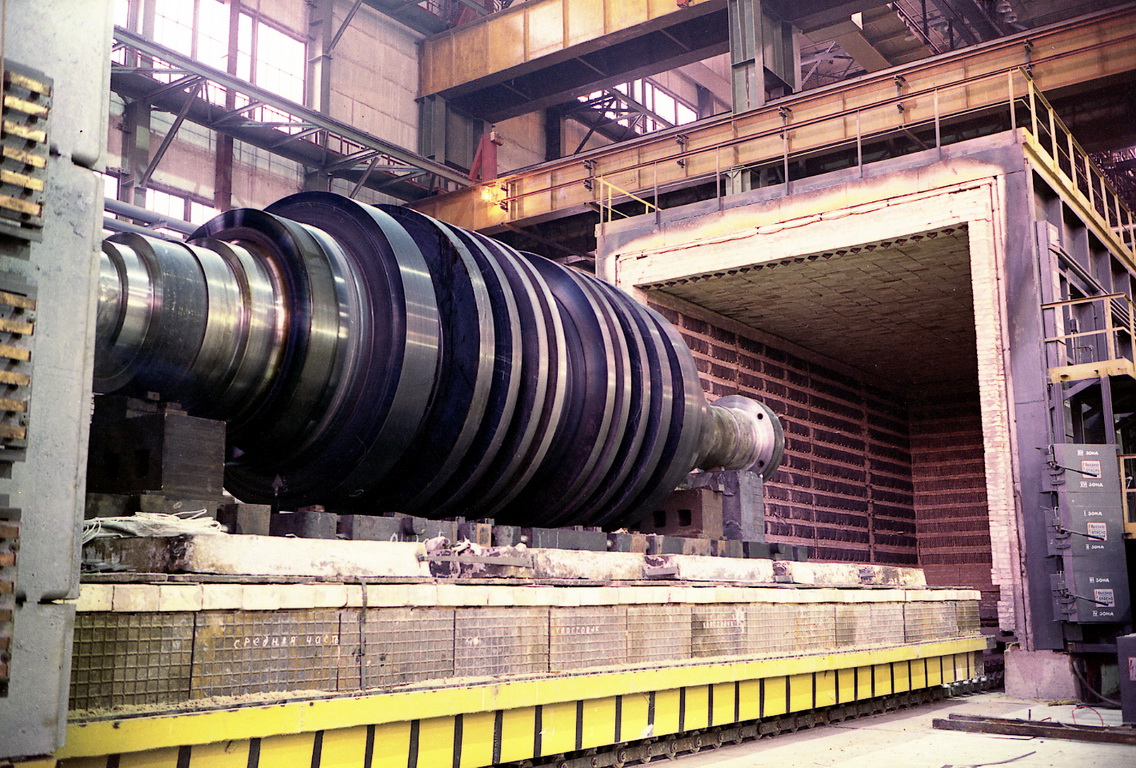

Thermal production has following capabilities:

Surface treatment (nitride) of items with size 600×650×2100 mm

Releasing of internal stresses after welding with load up to 200 tons:

- Shaft furnace - - Ø 8000×4500 mm,

- Furnace with roll-out tray - 5000×12000×450 mm

Thermal treatment:

- Ensuring of mechanical properties for long-length parts ay vertical condition Ø 500×2250 mm

- Parts in chlorhydric and saltpeter bathes Ø 200 × 450 mm

Special processes of metallurgical production included in Quality Management System "UKRENERGYMACHINES", JSC which supports requirement of international standard ISO 9001: 2008.

"UKRENERGYMACHINES", JSC is a member of Association of Foundries of Ukraine.