Welding Production

Prepared production has the following features:

- Oxygen cutting carbon and low-alloy steels with a thickness of 4 to 160 mm in any configuration (manual cutters, semiautomatic, flange-cuts, ASH-70, CNC machines).

- Plasma cutting high-alloy steels, nonferrous metals, thicknesses from 6 to 56 mm.

- Mechanical cutting:

- guillotine - up to 16mm thickness;

- circular shears - thickness 4 mm;

- press-cutters - corner 100x100x10 mm;

- mechanical hacksaw - Ø 159 mm.

- Bending of steel:

- with a yield point up to 400 ... 500MPa;

- thickness up to 120 mm (depending on width);

- maximum width of rollers - 5 meters;

- rolling of corner – 50x50x5 mm.

- Bending of tubes on the machine with HFC:

- carbon steel - up to Ø219 mm;

- alloy steel - up to Ø159 mm.

- Rectifying of plates:

- at press - with thickness up to 160 mm;

- at roll-straightening machine - with thickness up to 40 mm.

Welding production has:

- Welding technology:

- carbon;

- heat-resistant;

- stainless steel;

- austenitic steels.

- Welding process:

- manual arc welding with covered electrodes (RDE);

- gas-shielded arc welding (MIG / MAG);

- automatic submerged arc welding (AWF);

- tungsten-arc inert-gas welding (TIG);

- semi-automatic arc welding in CO2.

- electron-beam welding

- Specialized areas:

- welded rotors with weight up to 200 tons (weld in a narrow submerged treatment);

- orbital TIG welding joints "tube-tube plate (for heat exchangers);

- arc spraying (aluminum) parts of hydraulic turbines;

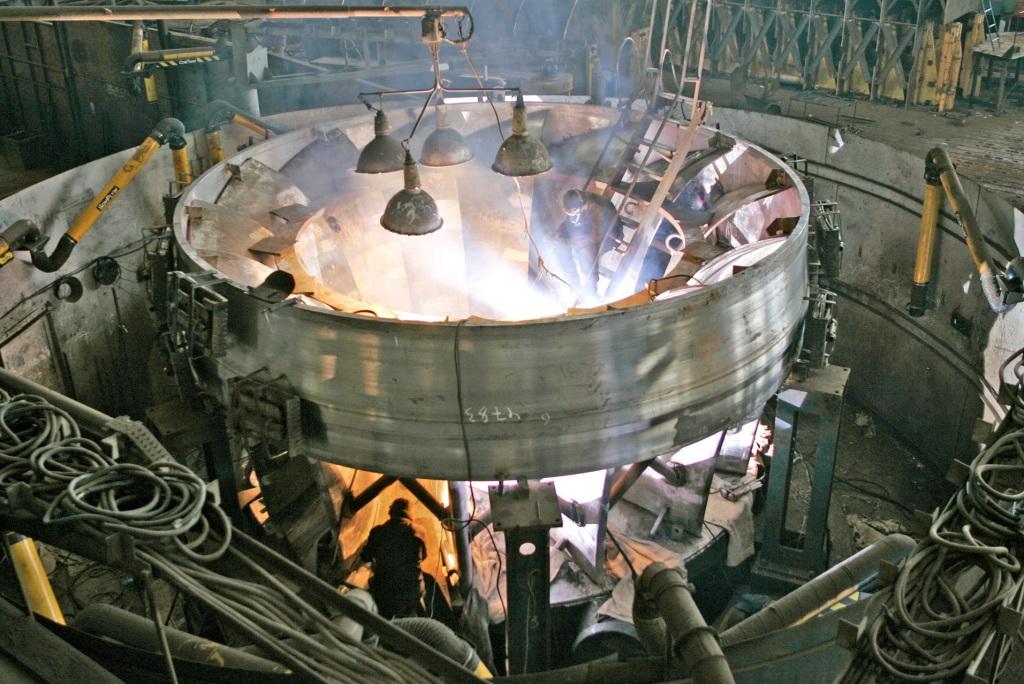

- welding of Francis runners;

- welded stamped blades.

- electron-beam welding of packages of steam turbine blades

- Furnaces for heat treatment of welded structures:

- length up to 13 meters

- height up to 4 meters

- width up to 5 meters,

- weight up to 200 tons.

Welding production occupies 30-35% of all production areas of the plant and has a manufacturing capacity for about 30 thousand tons of welded structures per year.

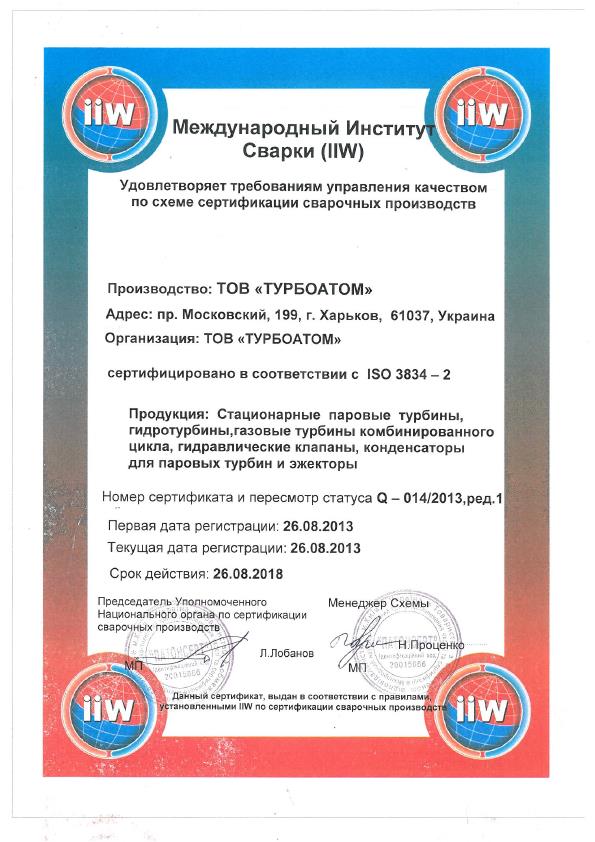

Welding production certified under requirements of ISO 3834-2:2005, Certificate No Q-014/2013 dated 26.08.2013.

Welding production has the permission of the Main Directorate of the city in Kharkov region to carry out welding, gas-flame and surfacing works.

Permission for conducting certification of welders for admission to implementation of work:

- with manual arc welding, MAW;

- with welding fusible electrode in active gases MAG;

- welding tungsten electrode in inert gas TIG;

- submerged arc welding SAW.

Department of Chief Welder has qualified personnel on welding production, including international level.

|

|

The main activities of Chief Welder Department:

- development of technology for preliminary works;

- development of technology for welded structures;

- design development of non-standard equipment and tooling for welding;

- rate setting of works in pre-production and welding production;

- equipment for welding with new welding equipment;

- research and development works on welding with assistance of Scientific Research Institutes, including IEW named after E.O.Paton.