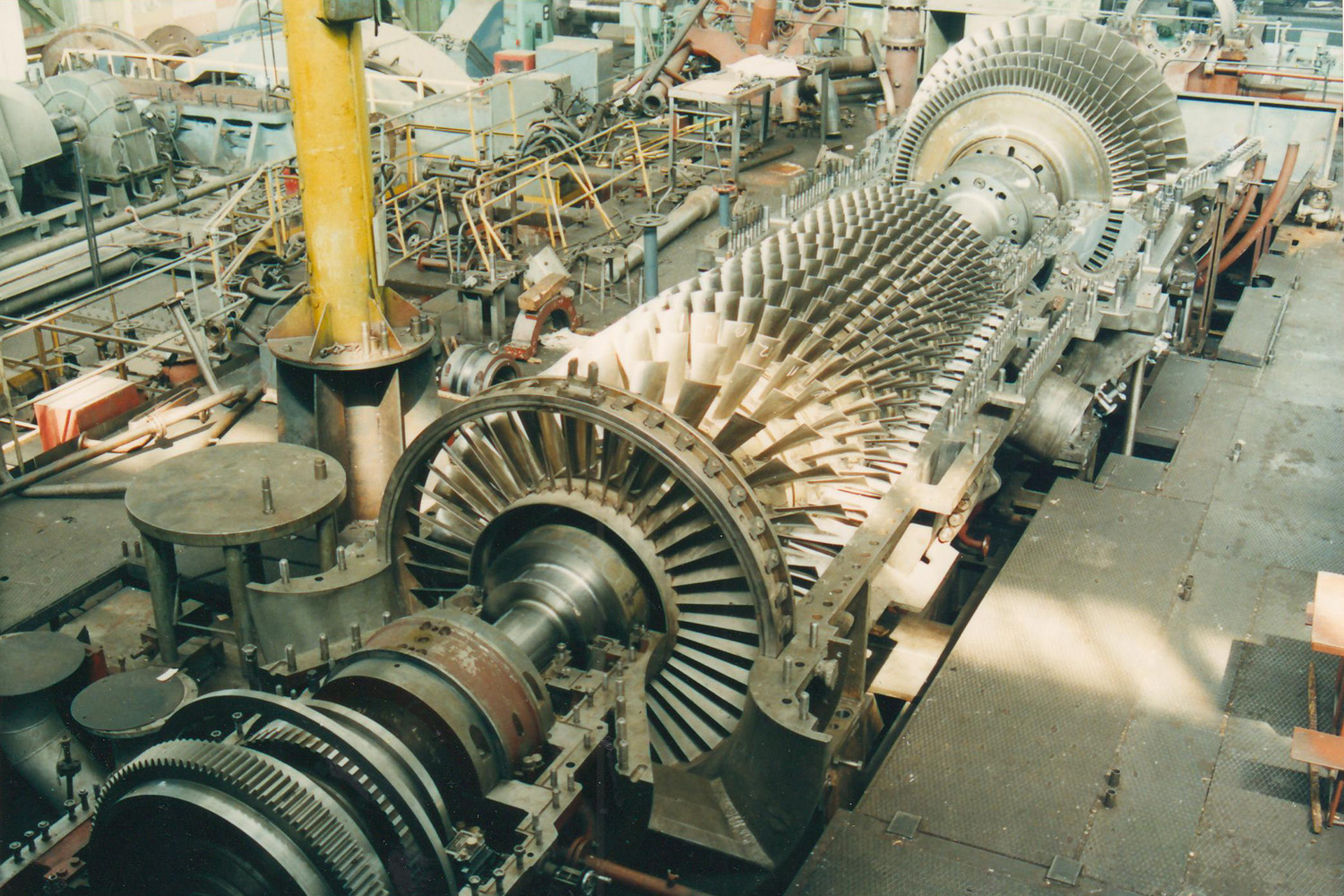

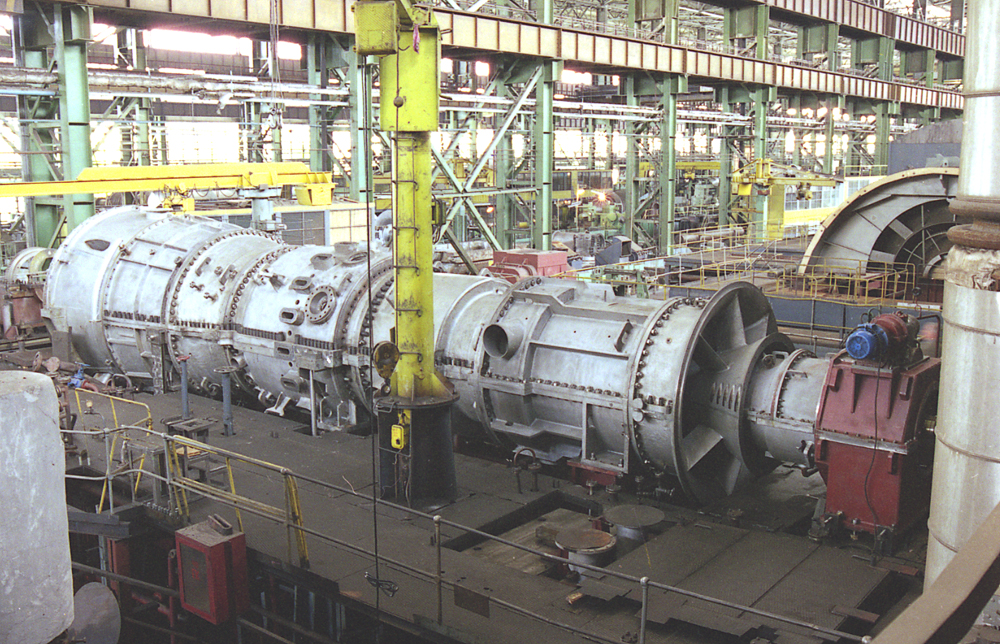

Since 1990 a new phase of cooperation with China and Cuba began. During the 1990-1993 "Turboatom" had supplied the turbine plants with a capacity of 320 MW for thermal power plants under construction for Nanjing and Yingkou (China). For TPP Havana in Cuba turbine K-220-130/3600 was designed and manufactured in 1991.

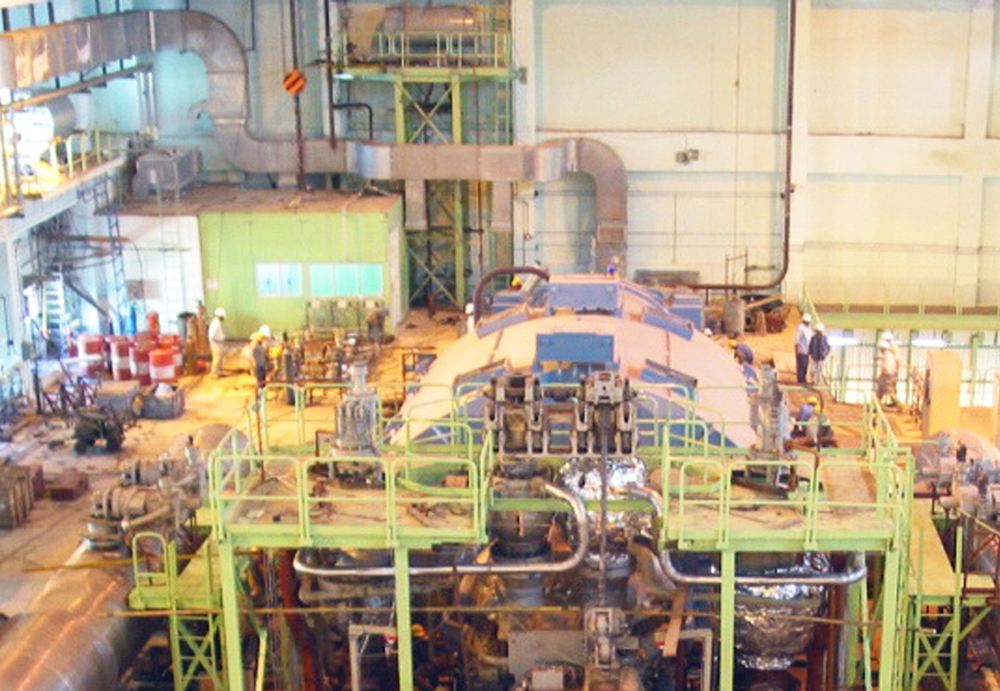

In period from 1996 to 2003, “Turboatom” won tenders for the first time independently and competitively and modernized turbines for NPP “Paksi” (Hungary) and NPP “Loviisa” (Finland).

One of the main activities of the enterprise in the period 1990-2000 was involvement in reconstruction and modernization of obsolete power equipment of hydroelectric power plant. Since 1996, enterprise has actively participated in modernization of power plants of Dnieper series, manufacturing hydroturbines with improved energy qualities, increased reliability and environmental friendliness.

The first environmentally friendly modernized turbine of adjustable blades, developed at the plant, was hydro turbine for Kamskaya HPP. A difference in design of the runner was absence of oil in the cavity of its housing in zone of blades sealing, as well as links of kinematics, bearings of blade pins operating on self-lubricating composite materials.

For 1996-2002, 18 sets of hydroturbine equipment were supplied for implementation of the first stage of rehabilitation of Dnieper series of HPP, including for Kyiv HPP, Dnieper HPP-1, and Kakhovka HPP.

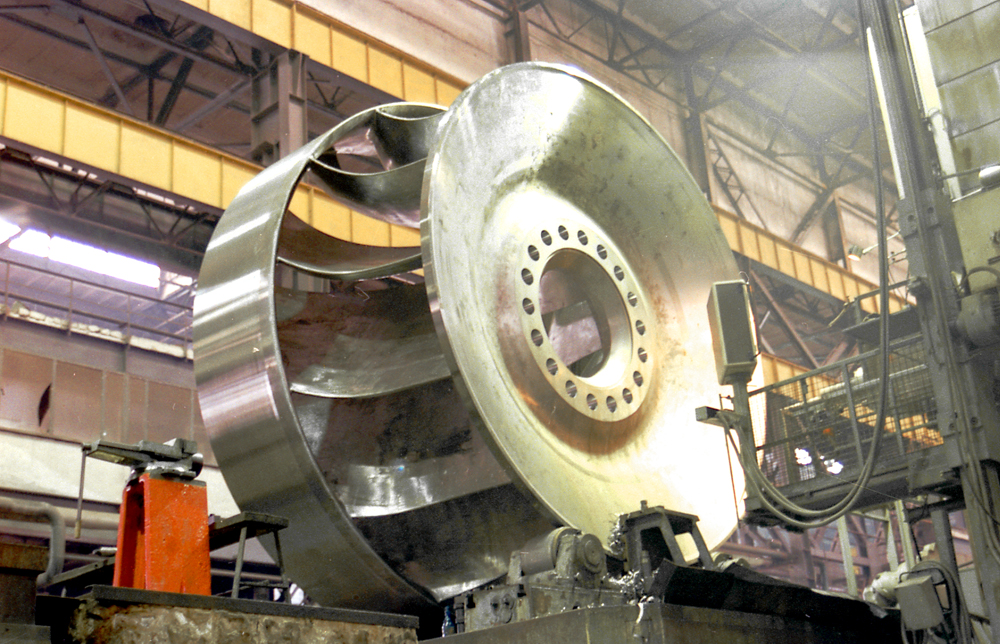

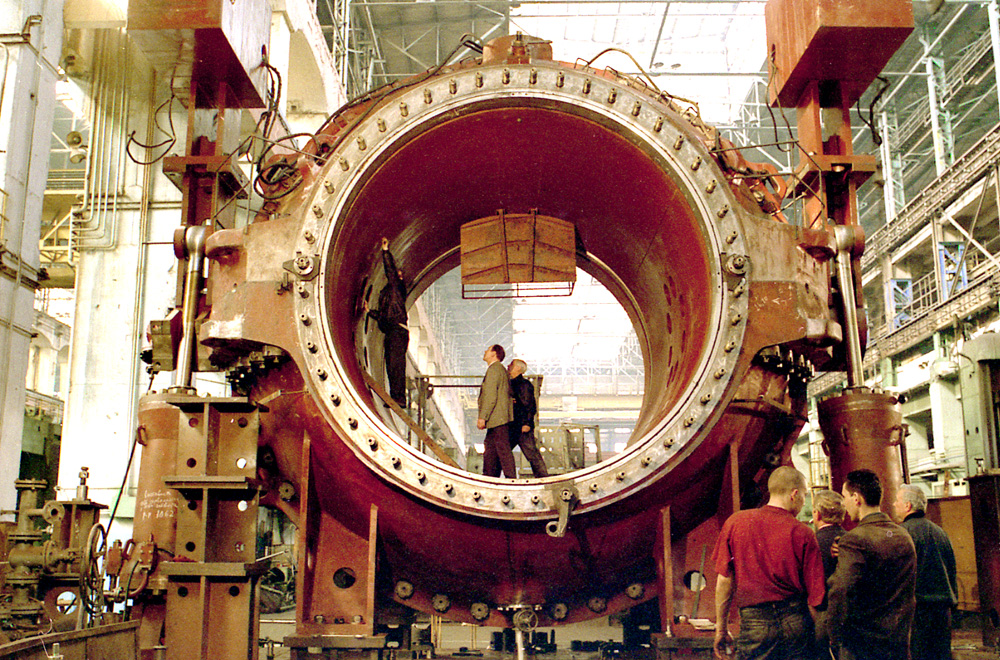

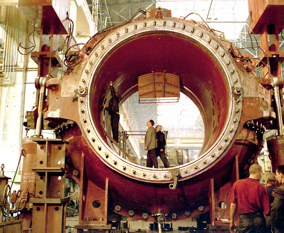

In January 1998, one of the largest export contracts for the supply of turbines to India for the “Tehri” hydroelectric complex entered into force. Scope of Contract includes development, manufacture, supply, installation and commissioning of hydraulic equipment consisting of: 4 radial-axial hydroturbines with single capacity of 280 MW, 4 unique spherical valves with diameter of 4 m and as many butterfly valves with diameter of 5 m. Tender for this order was attended by more than ten international firms.

During period 2000-2014 five of six hydroturbines of Dniester HPP-1 were rehabilitated and commissioned.

During period 2001 to 2003, contracts were also signed for the construction of HPPs Largi, Koteshwar, Turial for India, in cooperation with BHEL (India). OJSC "Turboatom" supplied in 2002-2003. 3 irunners with diameter of 3.45 m and capacity of 43.5 MW for HPP Largi, in 2007-2009. - 4 runners with diameter of 4.4 m and capacity of 102 MW for HPP Koteshwar, in 2013 - 3 runners with diameter of 2.65 m and capacity of 32.6 MW for HPP Turial.

Significant event in history of enterprise was signing in 2002 of contract with National Nuclear Energy Corporation of India (NPCIL) for supply of turbine equipment for four power units of two Indian NPPs “Kaiga” and “Rajasthan” with single capacity of 240 MW. The contract was successfully executed in 2006.

In 2003, second stage of modernization of Dnieper series of HPP began. For period 2003-2017 for PrJSC "Ukrhydroenergo", hydroturbine equipment for 45 units of Kiev HPP, Kakhovka HPP, Srednodniprovskaya HPP, Kanev HPP, Kremenchug HPP, Dneprovsk HPP-2 were rehabilitated and commissioned.

In Colombia, in 2003, two butterfly valves with diameters of 1.6 and 1.8 m and 2 spherical valves with a diameter of 0.9 m were supplied to HPP “Herradura” and HPP “Vuelta”.

From 2003 to 2005, two radial-axial hydroturbines with a built-in cylindrical valves with a unit capacity of 380.33 MW, with runner diameter 5.3 m, were developed, manufactured and supplied for HPP El Cajon (Mexico). In 2007, the hydraulic units of HPP El Cajon were commissioned.

High quality and confirmation by field tests of guaranteed technical and economic performance of equipment at HPP El Cajon became decisive factor in obtaining in 2008 analogous export order for two hydro-turbines RO 180-V-530 for HPP La Yesca (Mexico), and in 2009 supply of equipment to HPP was started. In 2012, hydraulic units of HPP La Yeska were commissioned.

Since 2004, works have been carried out to modernize 200 MW turbines at Starobeshevskaya, Kurakhovskaya and Luganskaya TPPs.

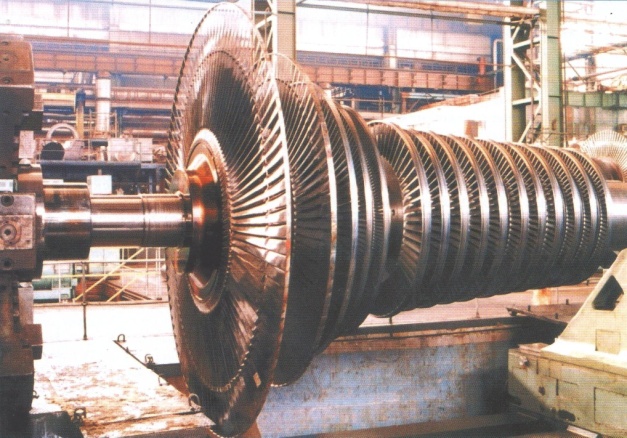

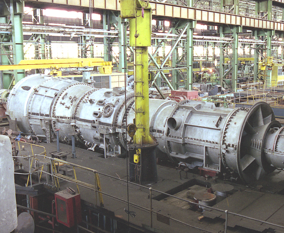

In 2005-2013 years. enterprise fulfilled a number of orders for supply of new generation turbines type K-325-23.5 for Zuevskaya TPP, TPP “Aksu” (Kazakhstan), SDTPP Novocherkasskaya, for development and implementation of which “Turboatom” was awarded with State Prize of Ukraine in field of science and technology in 2009. Membership of creative team includes General Director V. G. Subbotin, General Designer Ye. V. Levchenko and Chief Designer of Steam and Gas Turbines V. L. Shvetsov.

In 2006-2011 modernization of the flow parts of LPC of turbines K-500-65 / 3000 Leningrad, Kursk, Smolensk NPP. Works are performed on 21 turbines. Manufacture of pipe systems of NPP condensers made of titanium alloy and stainless steel has been established. Work was completed in 2011-2015 for the Novovoronezh, Balakovo, Rostov, Kalinin NPPs. Currently, work is being carried out at the South-Ukrainian and Zaporizhzhya NPPs.

In 2009 JSC "Turboatom" manufactured and supplied four sets of runners blades for adjustable blades hydroturbines of HPP In Pan (China) and four sets of runners for adjustable blades hydroturbines of Shengsigou (China) HPP.

In 2010, JSC “Turboatom” completed additional delivery of hydroturbine equipment for two radial-axial hydroturbines with ring valves of Rogun HPP (Tajikistan) with capacity of 200.0 MW with runner diameter of 4.835 m.

In 2011 JSC “Turboatom” fulfilled designing, manufacture, supply and commissioning of four radial-axial hydroturbines for Yegorlyk HPP-2 (Russia) with unit capacity of 3.0 MW with runner diameter of 1.9 m.

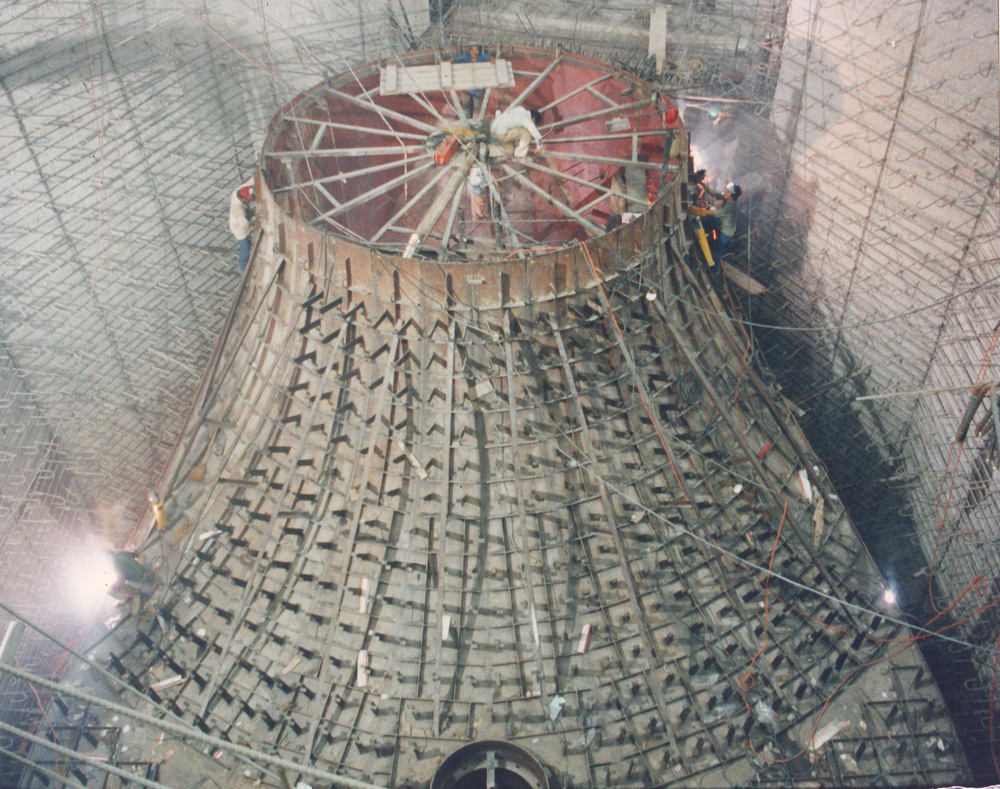

Dniester Hydro Pumped Storage Power Plant, which is being built in the central part of Dniester, should become an important stabilizing link in national power grid. Main equipment for this station was developed by leading Ukrainian power engineering companies, such as OJSC “Turboatom”, SE “Electrotyazhmash”, JSC “Zaporozhtransformator”, etc. OJSC “Turboatom” for DHPSPP developed vertical reversible radial-axial hydro turbine type ORO 170-V-730 with a built-in ring valve with unique parameters for the size of runner and capacity of hydraulic machine. Energy complex of Dniester HPSPP consists of seven hydroelectric units and is commissioned by several start-up lines. The first stage of HPSPP includes three hydroelectric units (designed capacity of 972 MW in generator mode and 1263 MW in pump mode). Since 2009, two hydraulic units have been commissioned. The first phase of three units was completed in 2016. At present, contract has been concluded and manufacture, supply and installation of the fourth hydraulic machine of the Dniester HPSPP is in progress.

From 2014 to 2017, following major works were carried out on hydroturbines:

- The last of 18 hydroturbines of Kamskaya HPP (Russia), modernized by JSC "Turboatom", was commissioned.

- Four modernized adjustable blades turbines of the Novosibirsk HPP (Russia) were commissioned. In total five hydraulic units were commissioned after modernization. The hydroturbine equipment of the sixth and seventh units is under construction.

- Two reversible radial-axial hydraulic machines of Zelenchukskaya HPP-HPSPP (Russia) have been commissioned.

- Two radial-axial hydroturbines of Gotsatlinskaya HPP (Russia) were commissioned.

- inspection, overhaul and commissioning of spherical valve with diameter of 4.2 m Nurek HPP (Tajikistan) was carried out.

- under contracts with IBRD, three adjustable blade hydroturbines of Dnieper HPP-2 were commissioned.

- under contracts with IBRD, two adjustable blade hydroturbines of Kremenchug HPP were commissioned, the third is under installation.

- commissioned the sixth, modernized adjustable blade hydroturbine of Srednedneprovsk HPP.

- in 2016 contract was signed (tender under EBRD and EIB) for rehabilitation of three hydraulic units with radial-axial turbines for the Kiev HPSPP. At present, implementation of this contract has been started.

- in 2016 contract was signed (tender under EBRD and EIB) for rehabilitation of seven units of Kanev HPP. At present, implementation of this contract has been started.

- in 2016, two contracts (single supplier) were concluded for rehabilitation of two units of Kanev HPP. At present, implementation of this contract has been started.

- in 2017, contracts were concluded for rehabilitation of Kakhovka HPP hydroturbine and supply of new shaft for hydroturbine of Srednedneprovsk HPP.

- in 2017, agreement was concluded for supply of spare (fifth) runner for radial-axial hydro turbine of HPP Largi, India.

From 2013 to 2015 following steam turbines were commissioned:

- turbine with capacity of 1100 MW Unit No 3 of Rostov NPP - the 19th low speed "million kilowatt turbine" K-1100-60 / 1500 manufactured by “Turboatom”, that was commissioned,

- turbine K-540-23,5 at Ekibastuz SDTPP (Kazakhstan),

- turbine K-325-23,3 with capacity of 325 MW at Zaporizhzhya and Trypilskaya TPPs, which replaced K-300-240-2, which exhausted its resource,

- turbine K-175-12,8 at Unit No. 8 of Dobrotvorsk TPP - modernized K-160-130,

- modernized turbine with replacement of condenser at Unit No 4 of Balakovo NPP.

- condensers of block-modular design with stainless steel pipe systems on Units No. 1 and 2 of Kalinin NPP were installed and commissioned.

Plant completed manufacture and shipment of the 20th "million kilowatt turbine" for the 4th Unit of Rostov NPP.

In 2014 contract was signed for manufacture and supply of two K-330-23.5 turbines in complete, modernization of the Unit No. 6 of Slavyansk TPP. Completion of work is planned for 2018.

In 2015, enterprise signed contract for modernization of HPC of power units No. 1-4 of NPP “Paksi”, Hungary. Completion of work is planned for 2019.

In 2017, JSC "Turboatom" concluded contract for modernization of HPC and LPC of 2 K-220-44 turbines, Unit No 2 of Metsamor NPP, Armenia. Completion of manufacture and shipment of equipment must be completed by January 2019.

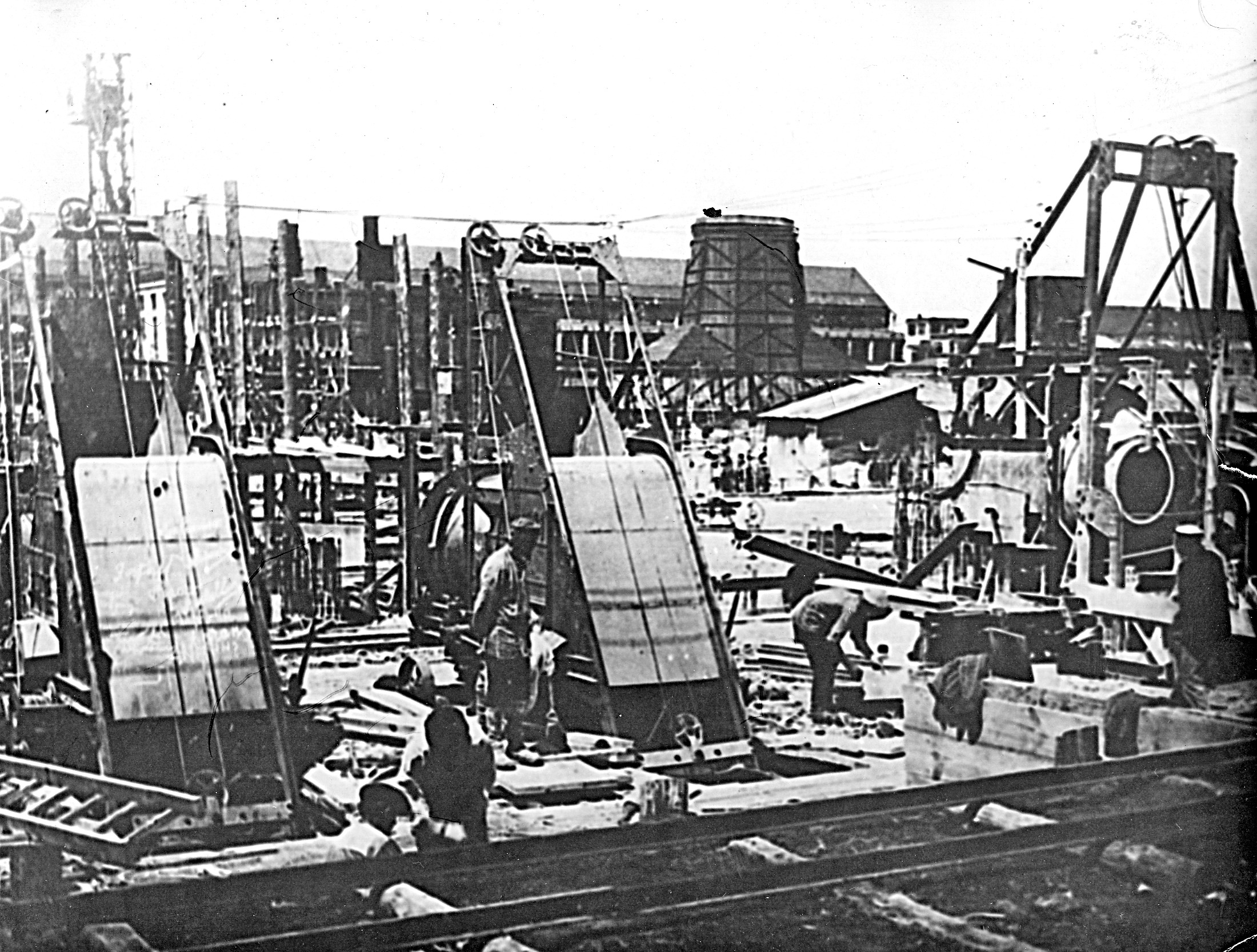

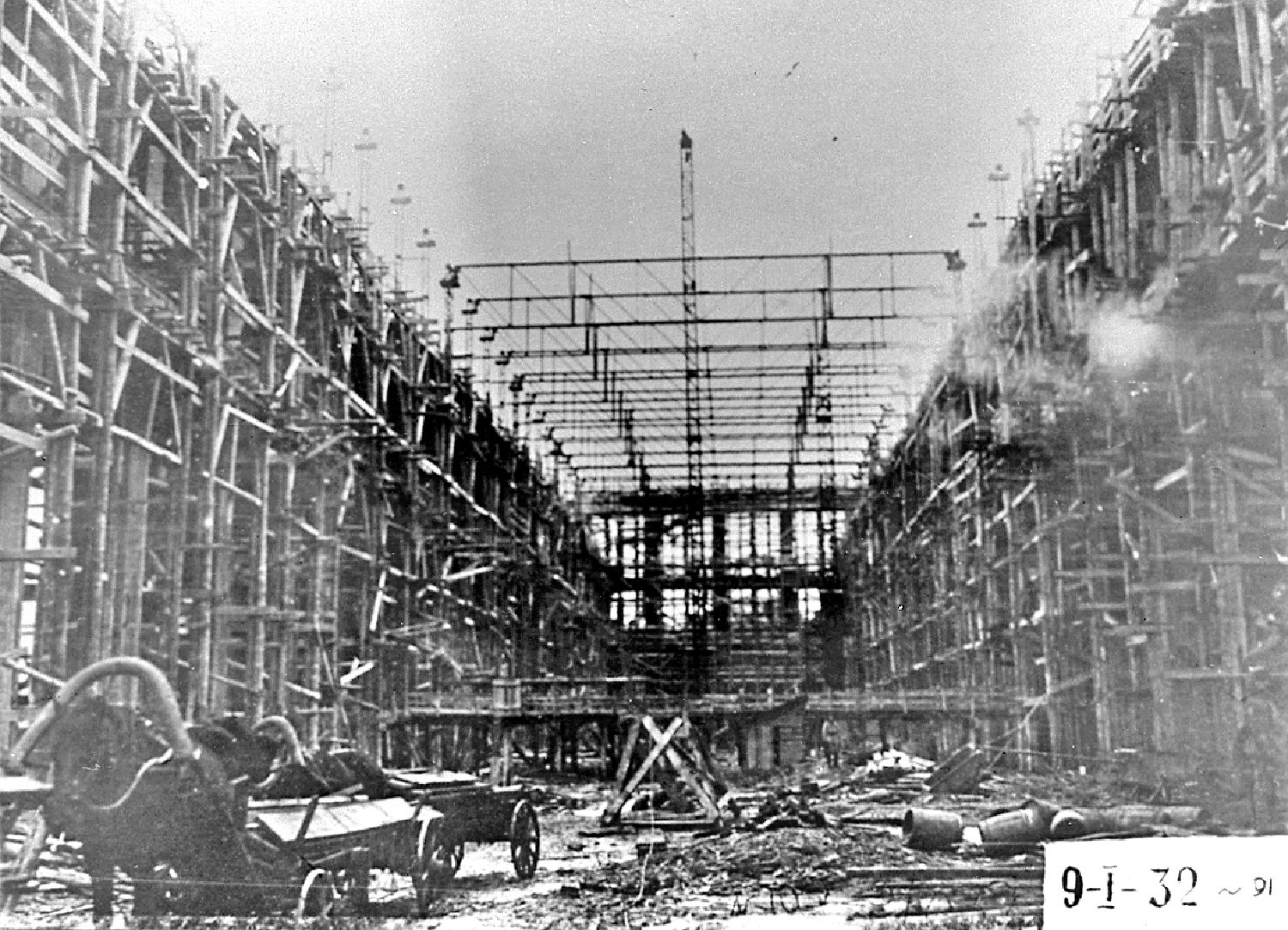

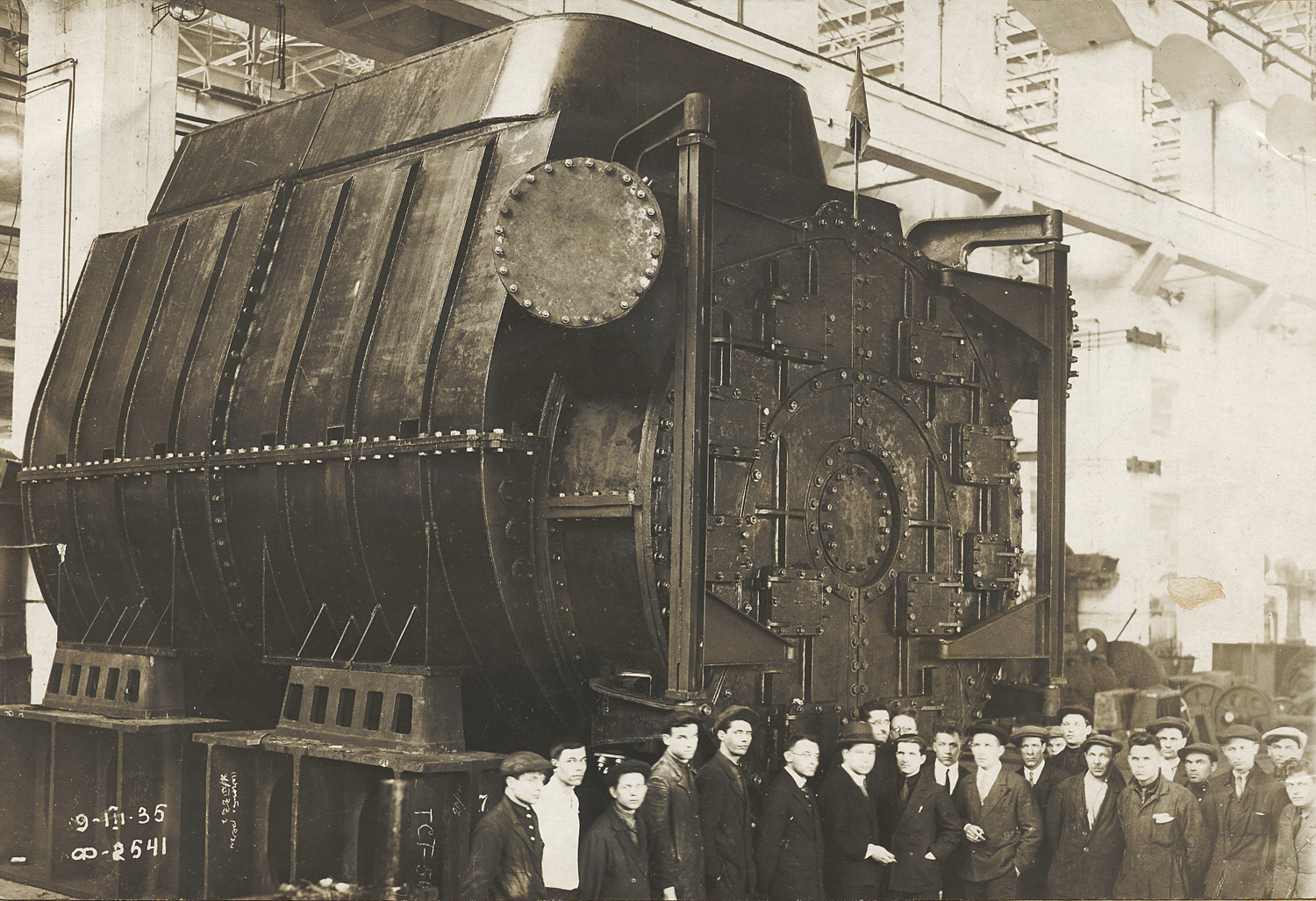

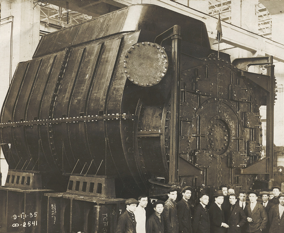

1929-1940

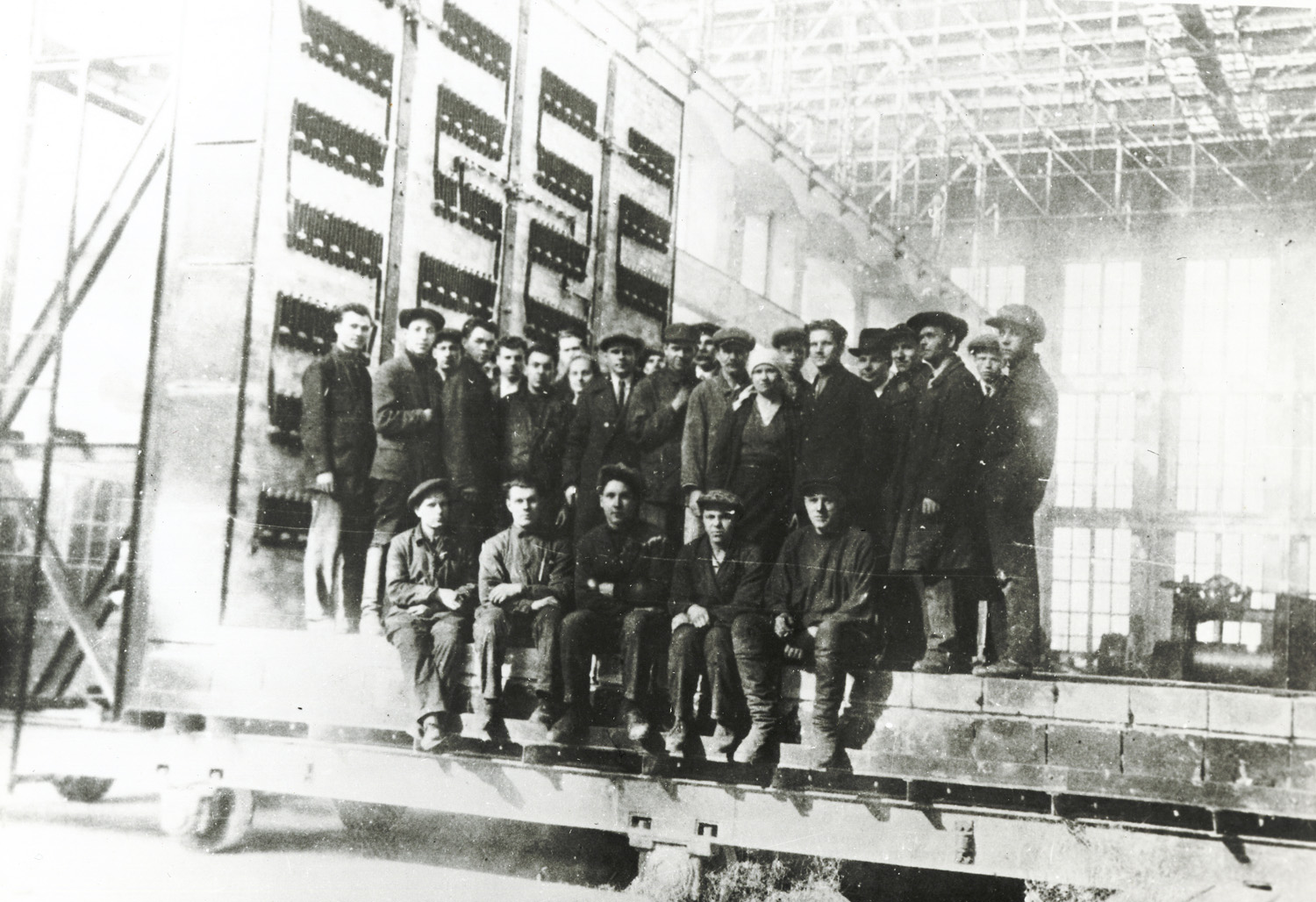

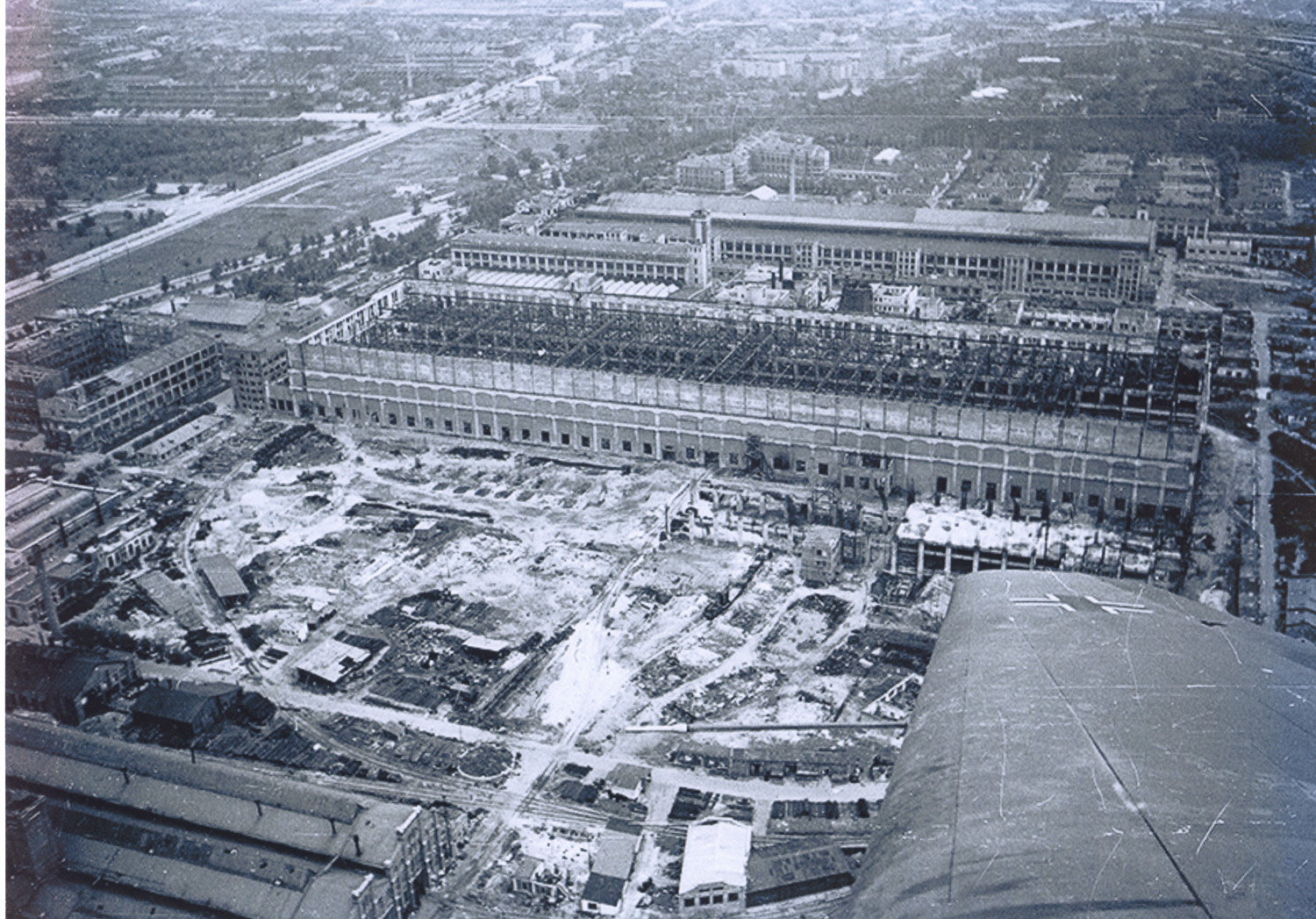

1929-1940 1940–1950

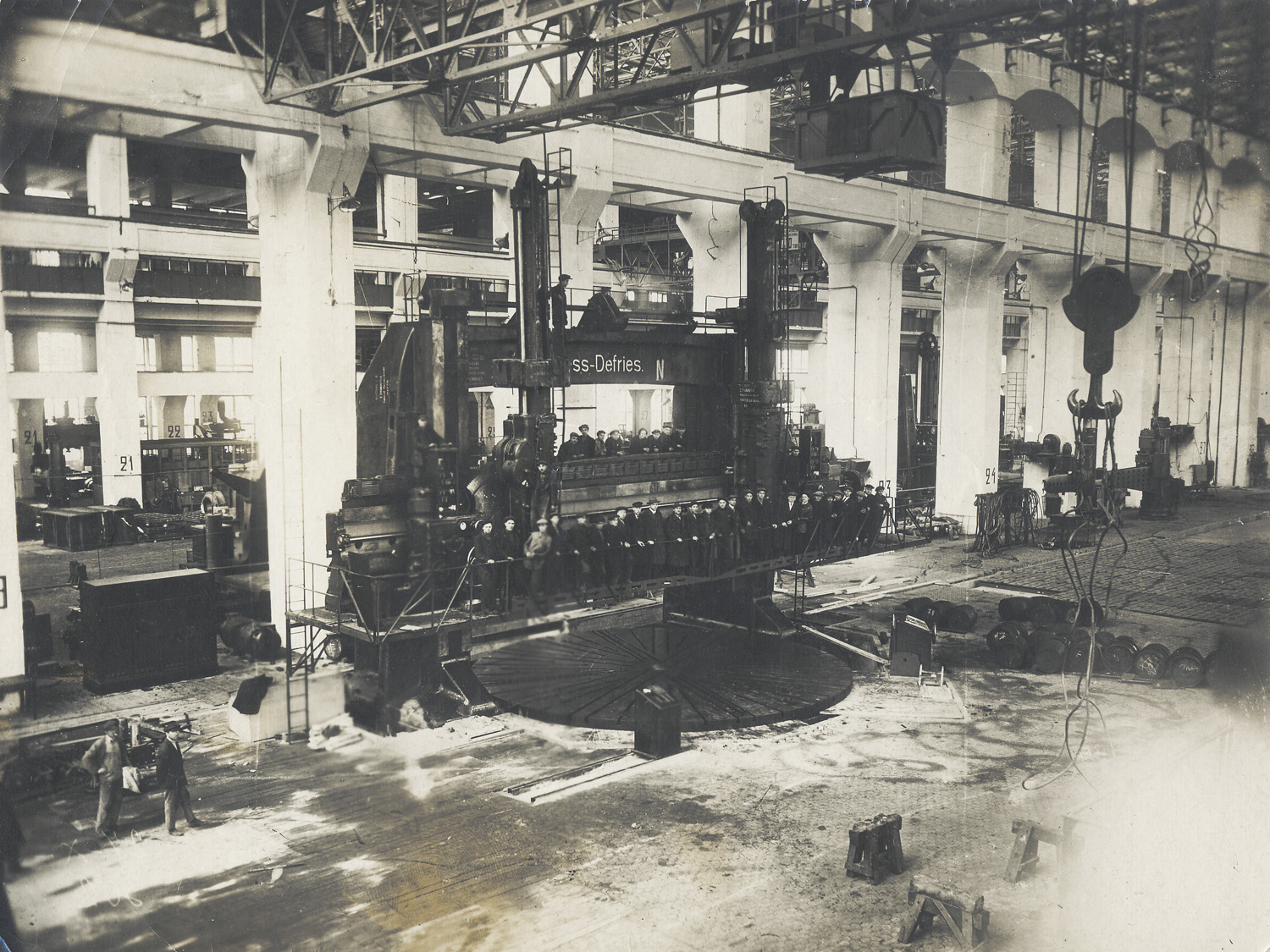

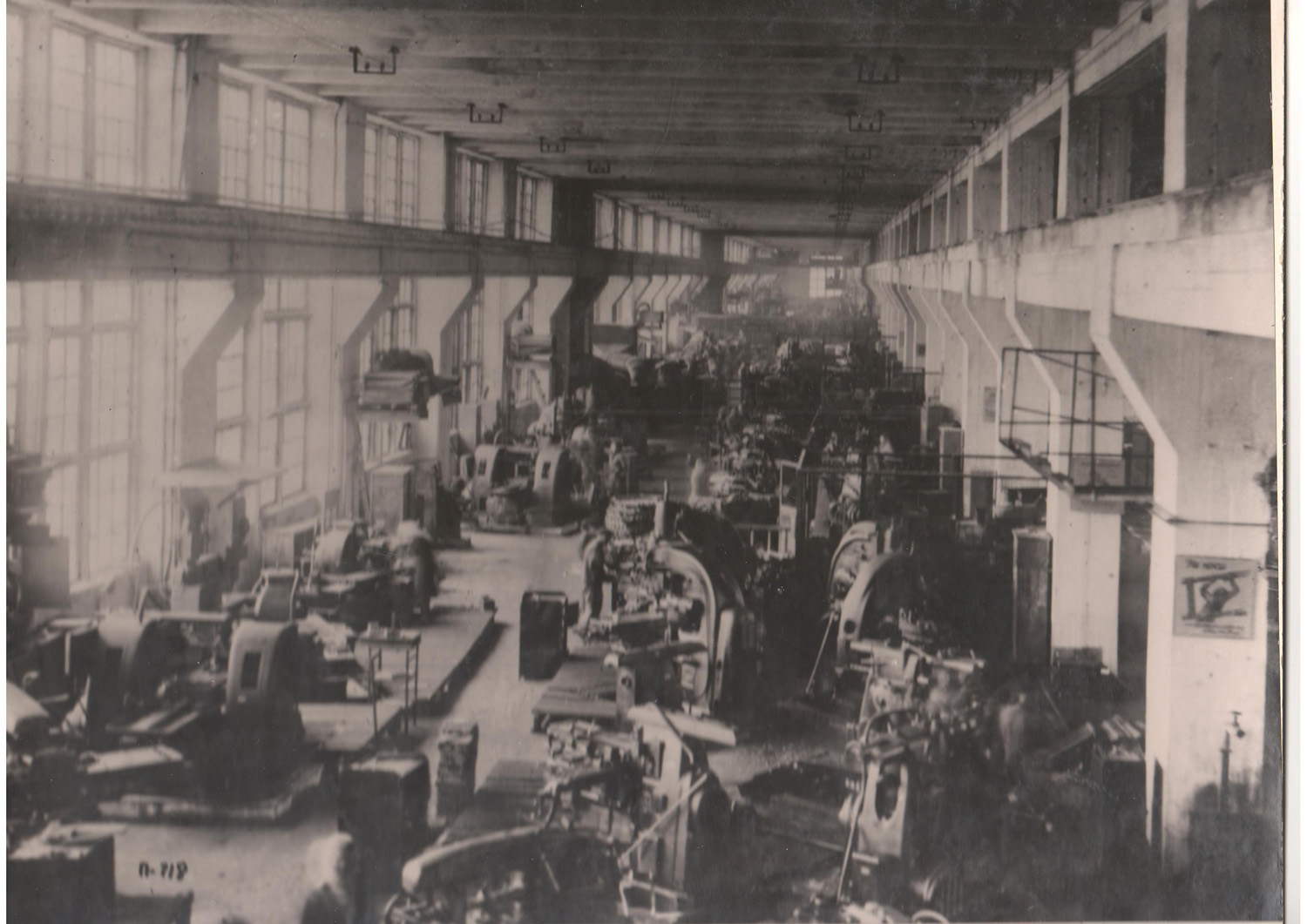

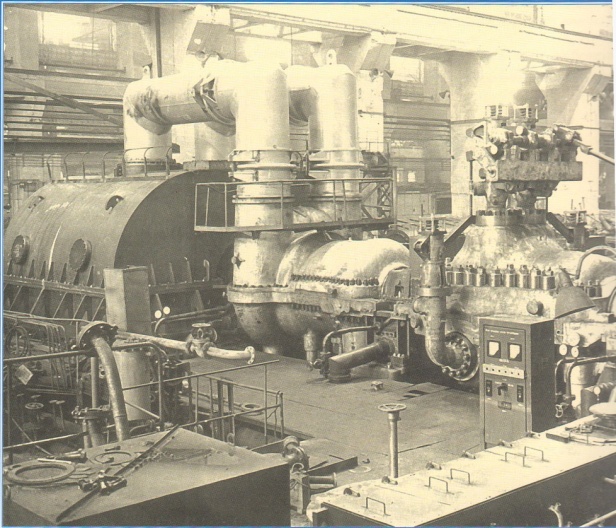

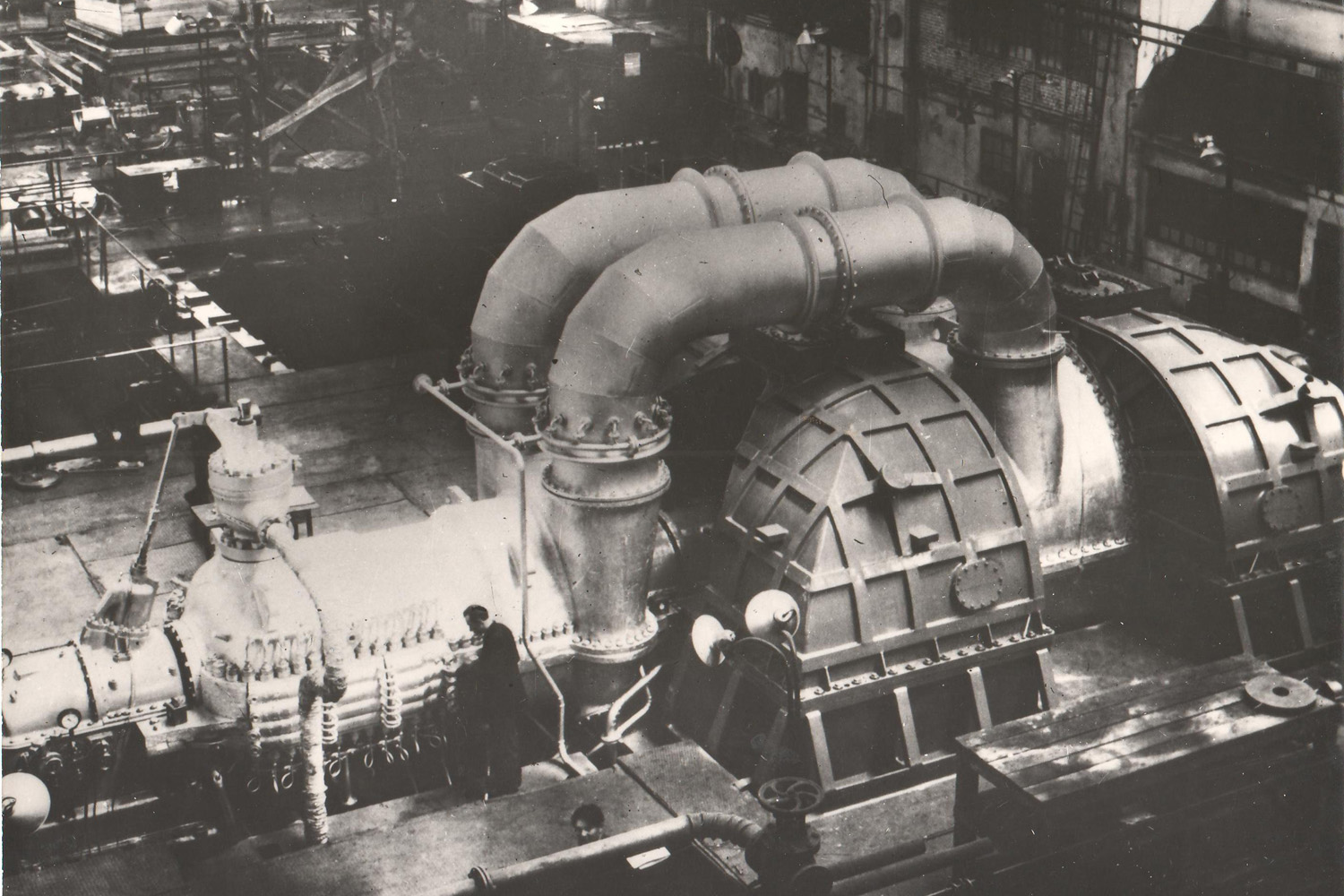

1940–1950 1950–1990

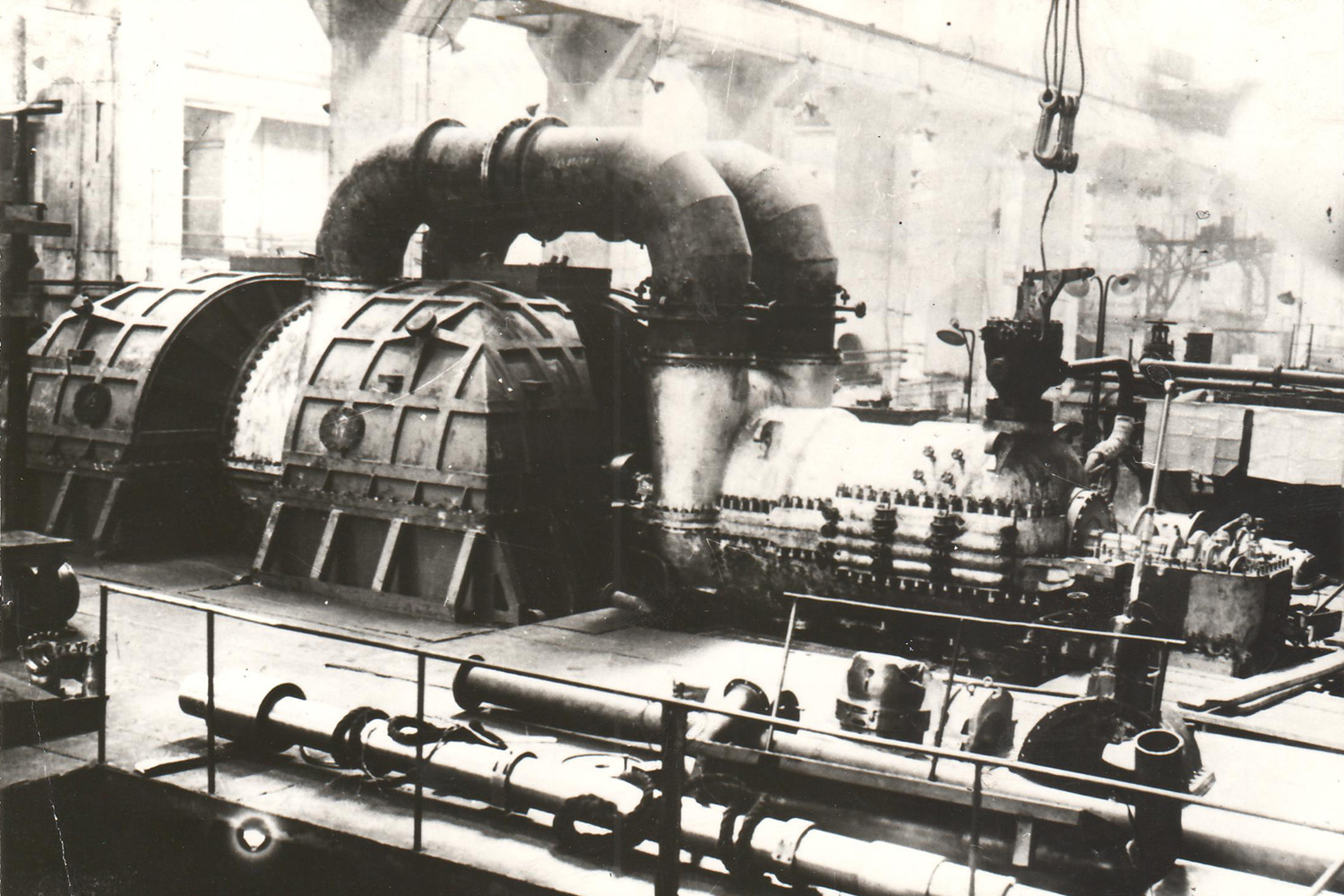

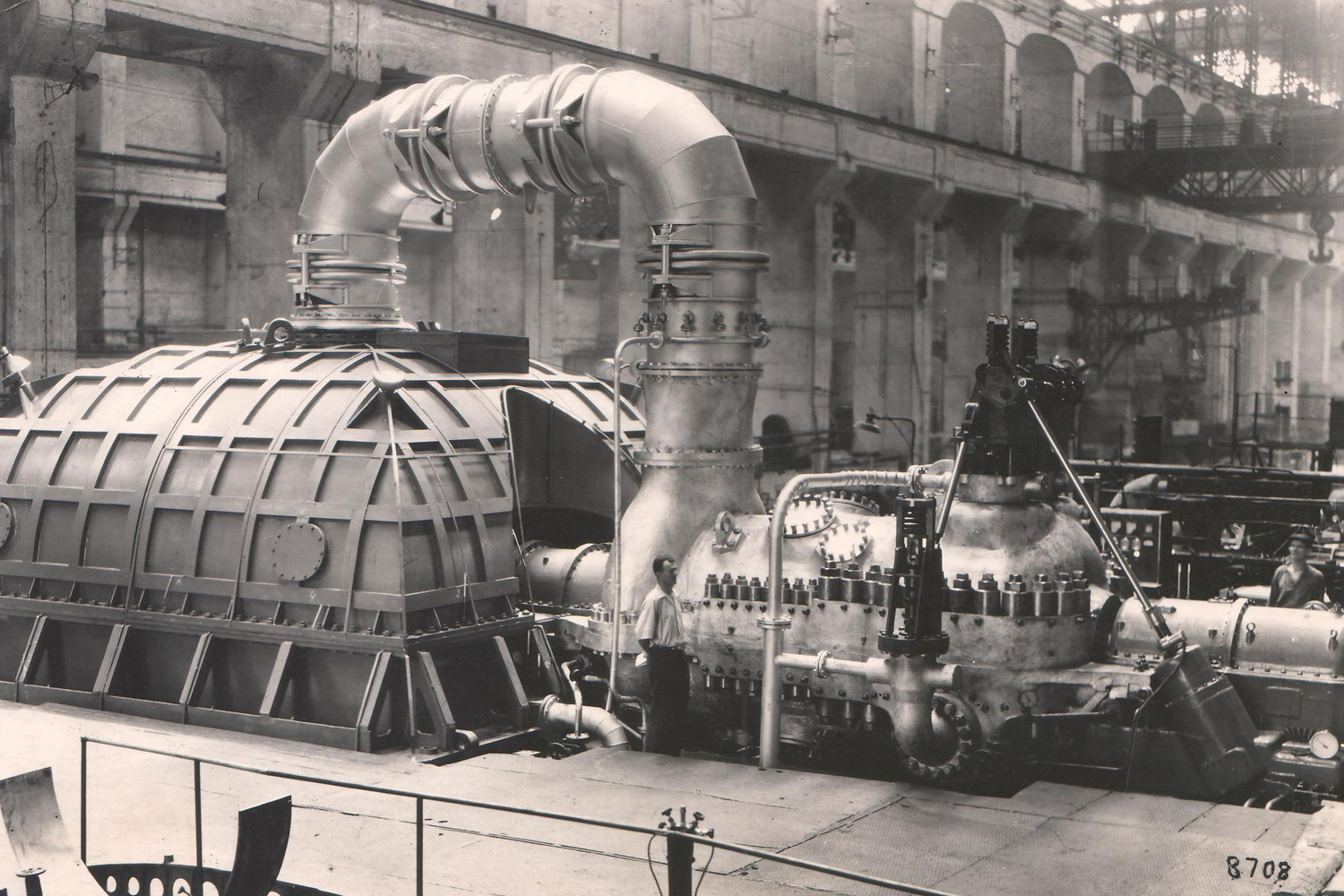

1950–1990 1990-

1990-